Page 399 - Injection Molding Advanced Troubleshooting Guide

P. 399

398 41 Sink

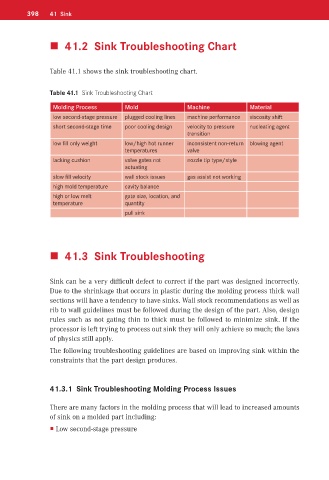

41.2 Sink Troubleshooting Chart

Table 41.1 shows the sink troubleshooting chart.

Table 41.1 Sink Troubleshooting Chart

Molding Process Mold Machine Material

low second-stage pressure plugged cooling lines machine performance viscosity shift

short second-stage time poor cooling design velocity to pressure nucleating agent

transition

low fill only weight low/high hot runner inconsistent non-return blowing agent

temperatures valve

lacking cushion valve gates not nozzle tip type/style

actuating

slow fill velocity wall stock issues gas assist not working

high mold temperature cavity balance

high or low melt gate size, location, and

temperature quantity

pull sink

41.3 Sink Troubleshooting

Sink can be a very difficult defect to correct if the part was designed incorrectly.

Due to the shrinkage that occurs in plastic during the molding process thick wall

sections will have a tendency to have sinks. Wall stock recommendations as well as

rib to wall guidelines must be followed during the design of the part. Also, design

rules such as not gating thin to thick must be followed to minimize sink. If the

processor is left trying to process out sink they will only achieve so much; the laws

of physics still apply.

The following troubleshooting guidelines are based on improving sink within the

constraints that the part design produces.

41.3.1 Sink Troubleshooting Molding Process Issues

There are many factors in the molding process that will lead to increased amounts

of sink on a molded part including:

Low second-stage pressure