Page 401 - Injection Molding Advanced Troubleshooting Guide

P. 401

400 41 Sink

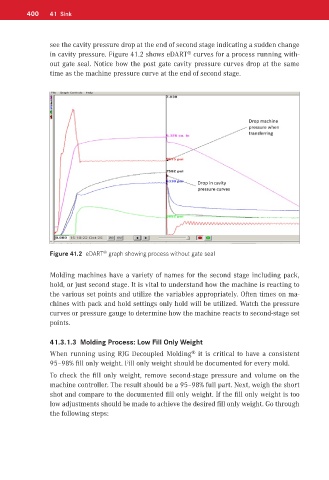

see the cavity pressure drop at the end of second stage indicating a sudden change

®

in cavity pressure. Figure 41.2 shows eDART curves for a process running with-

out gate seal. Notice how the post gate cavity pressure curves drop at the same

time as the machine pressure curve at the end of second stage.

Figure 41.2 eDART graph showing process without gate seal

®

Molding machines have a variety of names for the second stage including pack,

hold, or just second stage. It is vital to understand how the machine is reacting to

the various set points and utilize the variables appropriately. Often times on ma-

chines with pack and hold settings only hold will be utilized. Watch the pressure

curves or pressure gauge to determine how the machine reacts to second-stage set

points.

41.3.1.3 Molding Process: Low Fill Only Weight

When running using RJG Decoupled Molding it is critical to have a consistent

®

95–98% fill only weight. Fill only weight should be documented for every mold.

To check the fill only weight, remove second-stage pressure and volume on the

machine controller. The result should be a 95–98% full part. Next, weigh the short

shot and compare to the documented fill only weight. If the fill only weight is too

low adjustments should be made to achieve the desired fill only weight. Go through

the following steps: