Page 406 - Injection Molding Advanced Troubleshooting Guide

P. 406

41.3 Sink Troubleshooting 405

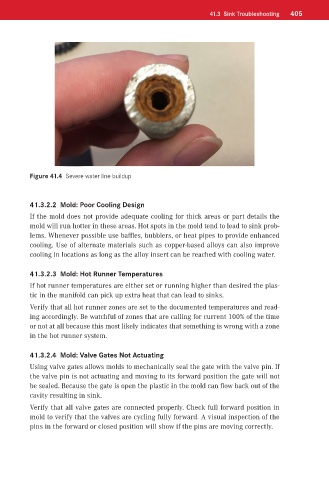

Figure 41.4 Severe water line buildup

41.3.2.2 Mold: Poor Cooling Design

If the mold does not provide adequate cooling for thick areas or part details the

mold will run hotter in these areas. Hot spots in the mold tend to lead to sink prob-

lems. Whenever possible use baffles, bubblers, or heat pipes to provide enhanced

cooling. Use of alternate materials such as copper-based alloys can also improve

cooling in locations as long as the alloy insert can be reached with cooling water.

41.3.2.3 Mold: Hot Runner Temperatures

If hot runner temperatures are either set or running higher than desired the plas-

tic in the manifold can pick up extra heat that can lead to sinks.

Verify that all hot runner zones are set to the documented temperatures and read-

ing accordingly. Be watchful of zones that are calling for current 100% of the time

or not at all because this most likely indicates that something is wrong with a zone

in the hot runner system.

41.3.2.4 Mold: Valve Gates Not Actuating

Using valve gates allows molds to mechanically seal the gate with the valve pin. If

the valve pin is not actuating and moving to its forward position the gate will not

be sealed. Because the gate is open the plastic in the mold can flow back out of the

cavity resulting in sink.

Verify that all valve gates are connected properly. Check full forward position in

mold to verify that the valves are cycling fully forward. A visual inspection of the

pins in the forward or closed position will show if the pins are moving correctly.