Page 402 - Injection Molding Advanced Troubleshooting Guide

P. 402

41.3 Sink Troubleshooting 401

1. Verify that the machine is running with an adequate cushion (minimum of

approximately 0.25 in).

2. If machine is holding a cushion, try reducing the transfer position.

3. If machine is not holding a cushion see Section 41.3.1.4.

4. Adjust shot if lack of cushion is due to shot size.

41.3.1.4 Molding Process: Lacking Cushion

To transfer pressure from the machine to the cavity the machine must have a cush-

ion of plastic in front of the screw tip. Cushion is a valuable variable to document

and track. If the machine is not holding a cushion, determine where the plastic is

going. Possible areas of leaking are:

Past non-return valve

Between nozzle tip and sprue bushing

In hot runner manifold

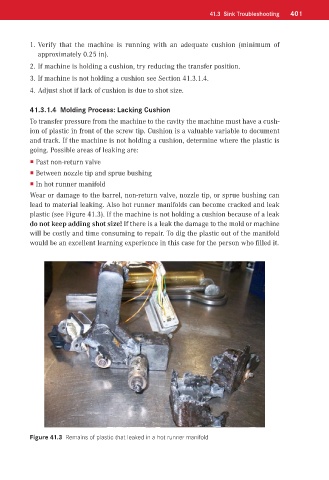

Wear or damage to the barrel, non-return valve, nozzle tip, or sprue bushing can

lead to material leaking. Also hot runner manifolds can become cracked and leak

plastic (see Figure 41.3). If the machine is not holding a cushion because of a leak

do not keep adding shot size! If there is a leak the damage to the mold or machine

will be costly and time consuming to repair. To dig the plastic out of the manifold

would be an excellent learning experience in this case for the person who filled it.

Figure 41.3 Remains of plastic that leaked in a hot runner manifold