Page 407 - Injection Molding Advanced Troubleshooting Guide

P. 407

406 41 Sink

If all connections are correct and the valve is not cycling try to manually cycle the

solenoid valve to see if this will make the pin move. If the pin moves when the

solenoid is manually triggered inspect the open/close triggers or timers for the

gates in question. If the pin does not move when the solenoid is manually triggered

it may indicate that the air or hydraulics are not plugged in, the cylinder may be

leaking, or the solenoid valve may not be shifting.

41.3.2.5 Mold: Wall Stock Issues

Maintaining nominal wall stock is one of the fundamental design requirements for

plastics. Assuming that the part was designed correctly there can still be thick ar-

eas of wall stock in the mold. Any thick area will experience more shrink than the

surrounding wall stock, and the thick areas often cannot be adequately packed

because thin wall stock between the gate and thick areas will freeze off before the

thick area is packed. Examine wall stock either with a micrometer or by cutting a

cross section. Gates should be located in thicker wall stock regions to avoid gating

thin to thick and experiencing freeze off prior to packing the thick areas. Use cau-

tion when gating into details such as ribs that are thinner than wall stock because

they will freeze before the nominal wall is packed out, and only opening the gate

will not improve this problem.

There are a few things that can lead to mold-related wall stock concerns such as:

1. Core pins that have been cut too short leaving a thick section

If the sink is occurring behind a core pin check the depth of the core pin on the

molded part by either using a set of calipers to check depth or cut through the

part in the area of concern to check for thick spots. If the pin is short it must be

replaced to eliminate the thick section.

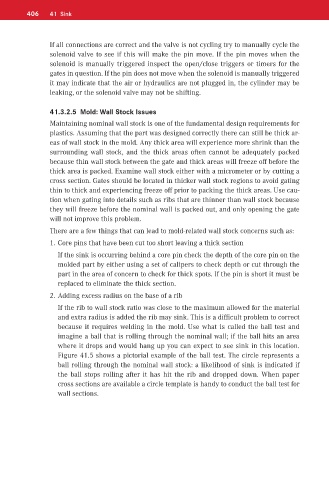

2. Adding excess radius on the base of a rib

If the rib to wall stock ratio was close to the maximum allowed for the material

and extra radius is added the rib may sink. This is a difficult problem to correct

because it requires welding in the mold. Use what is called the ball test and

imagine a ball that is rolling through the nominal wall; if the ball hits an area

where it drops and would hang up you can expect to see sink in this location.

Figure 41.5 shows a pictorial example of the ball test. The circle represents a

ball rolling through the nominal wall stock: a likelihood of sink is indicated if

the ball stops rolling after it has hit the rib and dropped down. When paper

cross sections are available a circle template is handy to conduct the ball test for

wall sections.