Page 411 - Injection Molding Advanced Troubleshooting Guide

P. 411

410 41 Sink

Machine velocity to pressure transfer problems can come from a number of things

including:

Pack or hold volume, speed, velocity set wrong. If these parameters are set wrong

the machine will not react well as it transfers. Adjust as required to provide a

better transfer.

Fill only weight too low. If the part is filled too short (below 95–98%) there will be

a lack of resistance as the machine transfers, which will often result in a poor

transfer. Adjust the fill only weight to match the documented process.

Machine valve tuning set wrong. If the valve tuning is not set correctly the ma-

chine will not react correctly at transfer. Machine valve tuning may need to be

adjusted to correct the problem.

41.3.3.3 Machine: Inconsistent Non-Return Valve

When a non-return valve is allowing plastic to leak, the cavity pressure will not

reach the desired level. Because the cavity pressure is low the result can be sink.

See Chapter 8 for details on measuring performance of a non-return valve.

If the non-return valve is leaking it will need to be replaced. There is a possibility

that the non-return valve is worn, broken, or contaminated with foreign material.

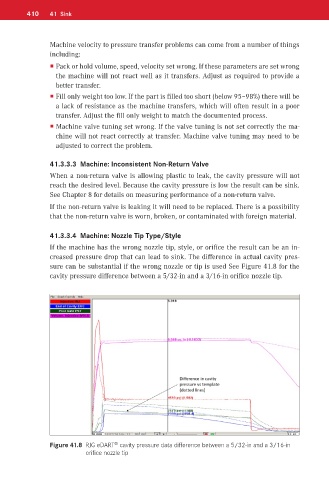

41.3.3.4 Machine: Nozzle Tip Type/Style

If the machine has the wrong nozzle tip, style, or orifice the result can be an in-

creased pressure drop that can lead to sink. The difference in actual cavity pres-

sure can be substantial if the wrong nozzle or tip is used See Figure 41.8 for the

cavity pressure difference between a 5/32-in and a 3/16-in orifice nozzle tip.

®

Figure 41.8 RJG eDART cavity pressure data difference between a 5/32-in and a 3/16-in

orifice nozzle tip