Page 415 - Injection Molding Advanced Troubleshooting Guide

P. 415

414 42 Splay

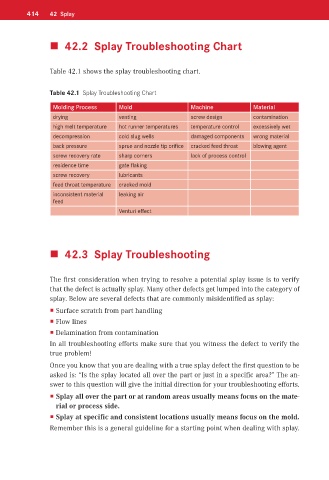

42.2 Splay Troubleshooting Chart

Table 42.1 shows the splay troubleshooting chart.

Table 42.1 Splay Troubleshooting Chart

Molding Process Mold Machine Material

drying venting screw design contamination

high melt temperature hot runner temperatures temperature control excessively wet

decompression cold slug wells damaged components wrong material

back pressure sprue and nozzle tip orifice cracked feed throat blowing agent

screw recovery rate sharp corners lack of process control

residence time gate flaking

screw recovery lubricants

feed throat temperature cracked mold

inconsistent material leaking air

feed

Venturi effect

42.3 Splay Troubleshooting

The first consideration when trying to resolve a potential splay issue is to verify

that the defect is actually splay. Many other defects get lumped into the category of

splay. Below are several defects that are commonly misidentified as splay:

Surface scratch from part handling

Flow lines

Delamination from contamination

In all troubleshooting efforts make sure that you witness the defect to verify the

true problem!

Once you know that you are dealing with a true splay defect the first question to be

asked is: “Is the splay located all over the part or just in a specific area?” The an-

swer to this question will give the initial direction for your troubleshooting efforts.

Splay all over the part or at random areas usually means focus on the mate-

rial or process side.

Splay at specific and consistent locations usually means focus on the mold.

Remember this is a general guideline for a starting point when dealing with splay.