Page 416 - Injection Molding Advanced Troubleshooting Guide

P. 416

42.3 Splay Troubleshooting 415

42.3.1 Splay Troubleshooting Molding Process Related Issues

The following sections will deal with potential splay causes in the process in-

cluding:

Drying

High melt temperature

Decompression

Back pressure

Residence time

Screw recovery

Feed throat temperature

Inconsistent material feed

42.3.1.1 Molding Process: Drying

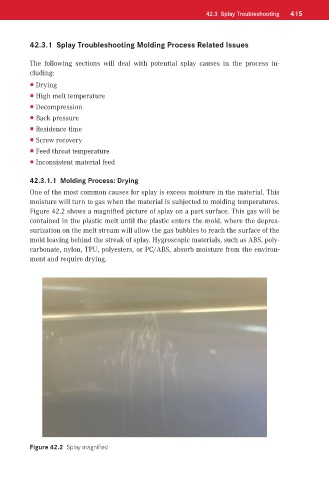

One of the most common causes for splay is excess moisture in the material. This

moisture will turn to gas when the material is subjected to molding temperatures.

Figure 42.2 shows a magnified picture of splay on a part surface. This gas will be

contained in the plastic melt until the plastic enters the mold, where the depres-

surization on the melt stream will allow the gas bubbles to reach the surface of the

mold leaving behind the streak of splay. Hygroscopic materials, such as ABS, poly-

carbonate, nylon, TPU, polyesters, or PC/ABS, absorb moisture from the environ-

ment and require drying.

Figure 42.2 Splay magnified