Page 429 - Injection Molding Advanced Troubleshooting Guide

P. 429

428 42 Splay

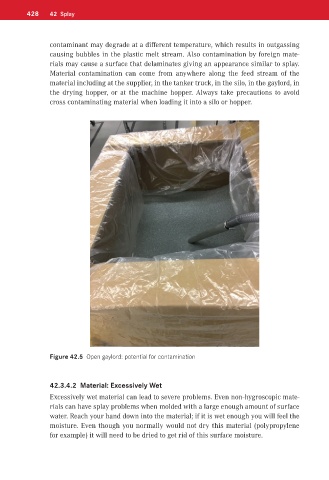

contaminant may degrade at a different temperature, which results in outgassing

causing bubbles in the plastic melt stream. Also contamination by foreign mate-

rials may cause a surface that delaminates giving an appearance similar to splay.

Material contamination can come from anywhere along the feed stream of the

material including at the supplier, in the tanker truck, in the silo, in the gaylord, in

the drying hopper, or at the machine hopper. Always take precautions to avoid

cross contaminating material when loading it into a silo or hopper.

Figure 42.5 Open gaylord: potential for contamination

42.3.4.2 Material: Excessively Wet

Excessively wet material can lead to severe problems. Even non-hygroscopic mate-

rials can have splay problems when molded with a large enough amount of surface

water. Reach your hand down into the material; if it is wet enough you will feel the

moisture. Even though you normally would not dry this material (polypropylene

for example) it will need to be dried to get rid of this surface moisture.