Page 432 - Injection Molding Advanced Troubleshooting Guide

P. 432

432 43 Sprue Sticking

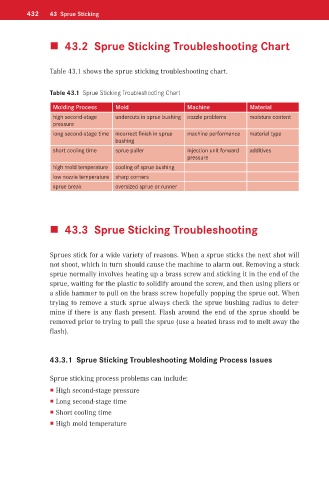

43.2 Sprue Sticking Troubleshooting Chart

Table 43.1 shows the sprue sticking troubleshooting chart.

Table 43.1 Sprue Sticking Troubleshooting Chart

Molding Process Mold Machine Material

high second-stage undercuts in sprue bushing nozzle problems moisture content

pressure

long second-stage time incorrect finish in sprue machine performance material type

bushing

short cooling time sprue puller injection unit forward additives

pressure

high mold temperature cooling of sprue bushing

low nozzle temperature sharp corners

sprue break oversized sprue or runner

43.3 Sprue Sticking Troubleshooting

Sprues stick for a wide variety of reasons. When a sprue sticks the next shot will

not shoot, which in turn should cause the machine to alarm out. Removing a stuck

sprue normally involves heating up a brass screw and sticking it in the end of the

sprue, waiting for the plastic to solidify around the screw, and then using pliers or

a slide hammer to pull on the brass screw hopefully popping the sprue out. When

trying to remove a stuck sprue always check the sprue bushing radius to deter-

mine if there is any flash present. Flash around the end of the sprue should be

removed prior to trying to pull the sprue (use a heated brass rod to melt away the

flash).

43.3.1 Sprue Sticking Troubleshooting Molding Process Issues

Sprue sticking process problems can include:

High second-stage pressure

Long second-stage time

Short cooling time

High mold temperature