Page 452 - Injection Molding Advanced Troubleshooting Guide

P. 452

452 45 Voids

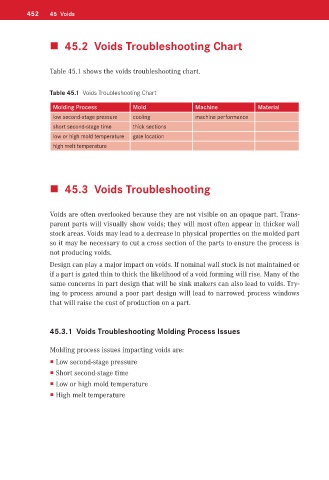

45.2 Voids Troubleshooting Chart

Table 45.1 shows the voids troubleshooting chart.

Table 45.1 Voids Troubleshooting Chart

Molding Process Mold Machine Material

low second-stage pressure cooling machine performance

short second-stage time thick sections

low or high mold temperature gate location

high melt temperature

45.3 Voids Troubleshooting

Voids are often overlooked because they are not visible on an opaque part. Trans-

parent parts will visually show voids; they will most often appear in thicker wall

stock areas. Voids may lead to a decrease in physical properties on the molded part

so it may be necessary to cut a cross section of the parts to ensure the process is

not producing voids.

Design can play a major impact on voids. If nominal wall stock is not maintained or

if a part is gated thin to thick the likelihood of a void forming will rise. Many of the

same concerns in part design that will be sink makers can also lead to voids. Try-

ing to process around a poor part design will lead to narrowed process windows

that will raise the cost of production on a part.

45.3.1 Voids Troubleshooting Molding Process Issues

Molding process issues impacting voids are:

Low second-stage pressure

Short second-stage time

Low or high mold temperature

High melt temperature