Page 260 - Inorganic Mass Spectrometry - Fundamentals and Applications

P. 260

246 Delmore

portion of the filament facing the lens is shortened by about a factor of 4, with a

voltage drop of 0.5 V or less across the face, and the sample concen~ated close to

for

the lens on the face of the filament. This design has been useful a variety of ex-

periments in which the approximate 0.5” spread across the ion ernitter does not

cause complications.

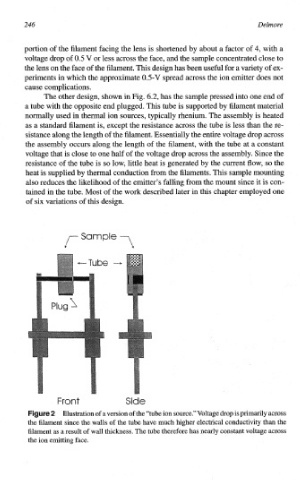

The other design, shown in Fig. 6.2, has the sample pressed into one end of

a tube with the opposite end plugged. This tube is supported by filament material

normally used in thermal ion sources, typically rhenium. The assembly is heated

as a standard filament is, except the resistance across the tube is less than the re-

sistance along the length of the filament. Essentially the entire voltage drop across

the assembly occurs along the length of the filament, with the tube at a constant

voltage that is close to one half of the voltage drop across the assembly. Since the

resistance of the tube is so low, little heat is generated by the current flow, so the

heat is supplied by thermal conduction from the filaments. This sample mounting

also reduces the likelihood of the emitter’s falling from the mount since it is con-

tained in the tube. Most of the work described later in this chapter employed one

of six variations of this design.

S

nt Sid

Illustration of a version of the “tube ion source.”Voltage is primarily across

drop

the fil~ent since the walls of the tube have much higher electrical conductivity than the

wall thickness. The tube therefore has nearly constant voltage across

filament as a result of

the ion emitting face.