Page 212 -

P. 212

194 CHAPTER 6 The Production Process

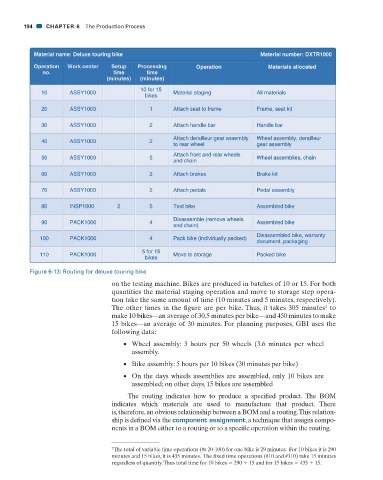

Figure 6-13: Routing for deluxe touring bike

on the testing machine. Bikes are produced in batches of 10 or 15. For both

quantities the material staging operation and move to storage step opera-

tion take the same amount of time (10 minutes and 5 minutes, respectively).

The other times in the fi gure are per bike. Thus, it takes 305 minutes to

2

make 10 bikes—an average of 30.5 minutes per bike—and 450 minutes to make

15 bikes—an average of 30 minutes. For planning purposes, GBI uses the

following data:

• Wheel assembly: 3 hours per 50 wheels (3.6 minutes per wheel

assembly.

• Bike assembly: 5 hours per 10 bikes (30 minutes per bike)

• On the days wheels assemblies are assembled, only 10 bikes are

assembled; on other days, 15 bikes are assembled

The routing indicates how to produce a specifi ed product. The BOM

indicates which materials are used to manufacture that product. There

is, therefore, an obvious relationship between a BOM and a routing. This relation-

ship is defi ned via the component assignment, a technique that assigns compo-

nents in a BOM either to a routing or to a specifi c operation within the routing.

2 The total of variable time operations (#s 20-100) for one bike is 29 minutes. For 10 bikes it is 290

minutes and 15 bikes, it is 435 minutes. The fi xed time operations (#10 and #110) take 15 minutes

regardless of quantity. Thus total time for 10 bikes 290 15 and for 15 bikes 435 15.

31/01/11 6:40 AM

CH006.indd 194 31/01/11 6:40 AM

CH006.indd 194