Page 197 - Intelligent Digital Oil And Gas Fields

P. 197

Workflow Automation and Intelligent Control 153

Process to be

Motivation automated Select the Define

(Define technology Decion making business

business goals) (Identify (toolkits & CPU) metric

repetitive tasks)

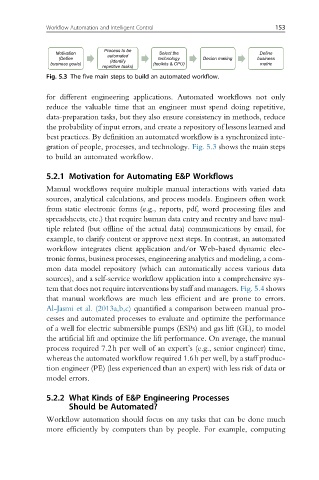

Fig. 5.3 The five main steps to build an automated workflow.

for different engineering applications. Automated workflows not only

reduce the valuable time that an engineer must spend doing repetitive,

data-preparation tasks, but they also ensure consistency in methods, reduce

the probability of input errors, and create a repository of lessons learned and

best practices. By definition an automated workflow is a synchronized inte-

gration of people, processes, and technology. Fig. 5.3 shows the main steps

to build an automated workflow.

5.2.1 Motivation for Automating E&P Workflows

Manual workflows require multiple manual interactions with varied data

sources, analytical calculations, and process models. Engineers often work

from static electronic forms (e.g., reports, pdf, word processing files and

spreadsheets, etc.) that require human data entry and reentry and have mul-

tiple related (but offline of the actual data) communications by email, for

example, to clarify content or approve next steps. In contrast, an automated

workflow integrates client application and/or Web-based dynamic elec-

tronic forms, business processes, engineering analytics and modeling, a com-

mon data model repository (which can automatically access various data

sources), and a self-service workflow application into a comprehensive sys-

tem that does not require interventions by staff and managers. Fig. 5.4 shows

that manual workflows are much less efficient and are prone to errors.

Al-Jasmi et al. (2013a,b,c) quantified a comparison between manual pro-

cesses and automated processes to evaluate and optimize the performance

of a well for electric submersible pumps (ESPs) and gas lift (GL), to model

the artificial lift and optimize the lift performance. On average, the manual

process required 7.2h per well of an expert’s (e.g., senior engineer) time,

whereas the automated workflow required 1.6h per well, by a staff produc-

tion engineer (PE) (less experienced than an expert) with less risk of data or

model errors.

5.2.2 What Kinds of E&P Engineering Processes

Should be Automated?

Workflow automation should focus on any tasks that can be done much

more efficiently by computers than by people. For example, computing