Page 193 - Intelligent Digital Oil And Gas Fields

P. 193

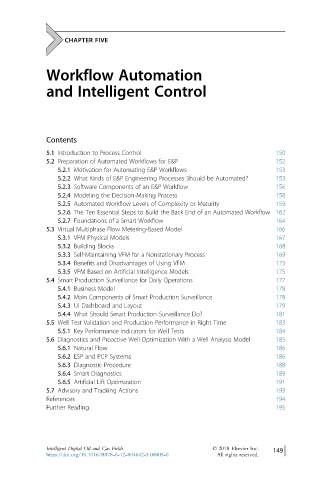

CHAPTER FIVE

Workflow Automation

and Intelligent Control

Contents

5.1 Introduction to Process Control 150

5.2 Preparation of Automated Workflows for E&P 152

5.2.1 Motivation for Automating E&P Workflows 153

5.2.2 What Kinds of E&P Engineering Processes Should be Automated? 153

5.2.3 Software Components of an E&P Workflow 156

5.2.4 Modeling the Decision-Making Process 158

5.2.5 Automated Workflow Levels of Complexity or Maturity 159

5.2.6 The Ten Essential Steps to Build the Back End of an Automated Workflow 162

5.2.7 Foundations of a Smart Workflow 164

5.3 Virtual Multiphase Flow Metering-Based Model 166

5.3.1 VFM Physical Models 167

5.3.2 Building Blocks 168

5.3.3 Self-Maintaining VFM for a Nonstationary Process 169

5.3.4 Benefits and Disadvantages of Using VFM 173

5.3.5 VFM Based on Artificial Intelligence Models 175

5.4 Smart Production Surveillance for Daily Operations 177

5.4.1 Business Model 178

5.4.2 Main Components of Smart Production Surveillance 178

5.4.3 UI Dashboard and Layout 179

5.4.4 What Should Smart Production Surveillance Do? 181

5.5 Well Test Validation and Production Performance in Right Time 183

5.5.1 Key Performance Indicators for Well Tests 184

5.6 Diagnostics and Proactive Well Optimization With a Well Analysis Model 185

5.6.1 Natural Flow 186

5.6.2 ESP and PCP Systems 186

5.6.3 Diagnostic Procedure 188

5.6.4 Smart Diagnostics 189

5.6.5 Artificial Lift Optimization 191

5.7 Advisory and Tracking Actions 193

References 194

Further Reading 195

Intelligent Digital Oil and Gas Fields © 2018 Elsevier Inc. 149

https://doi.org/10.1016/B978-0-12-804642-5.00005-0 All rights reserved.