Page 141 - Intro Predictive Maintenance

P. 141

132 An Introduction to Predictive Maintenance

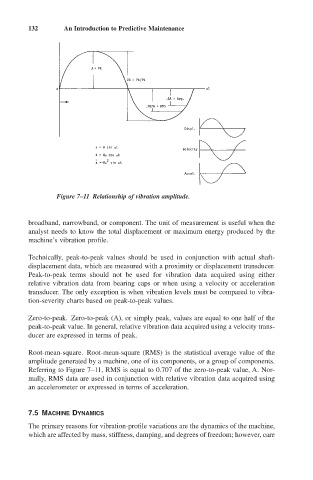

Figure 7–11 Relationship of vibration amplitude.

broadband, narrowband, or component. The unit of measurement is useful when the

analyst needs to know the total displacement or maximum energy produced by the

machine’s vibration profile.

Technically, peak-to-peak values should be used in conjunction with actual shaft-

displacement data, which are measured with a proximity or displacement transducer.

Peak-to-peak terms should not be used for vibration data acquired using either

relative vibration data from bearing caps or when using a velocity or acceleration

transducer. The only exception is when vibration levels must be compared to vibra-

tion-severity charts based on peak-to-peak values.

Zero-to-peak. Zero-to-peak (A), or simply peak, values are equal to one half of the

peak-to-peak value. In general, relative vibration data acquired using a velocity trans-

ducer are expressed in terms of peak.

Root-mean-square. Root-mean-square (RMS) is the statistical average value of the

amplitude generated by a machine, one of its components, or a group of components.

Referring to Figure 7–11, RMS is equal to 0.707 of the zero-to-peak value, A. Nor-

mally, RMS data are used in conjunction with relative vibration data acquired using

an accelerometer or expressed in terms of acceleration.

7.5 MACHINE DYNAMICS

The primary reasons for vibration-profile variations are the dynamics of the machine,

which are affected by mass, stiffness, damping, and degrees of freedom; however, care