Page 281 - Intro Predictive Maintenance

P. 281

272 An Introduction to Predictive Maintenance

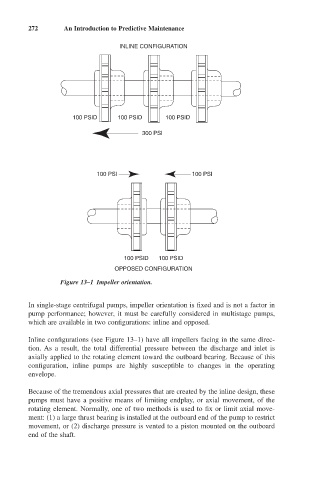

INLINE CONFIGURATION

100 PSID 100 PSID 100 PSID

300 PSI

100 PSI 100 PSI

100 PSID 100 PSID

OPPOSED CONFIGURATION

Figure 13–1 Impeller orientation.

In single-stage centrifugal pumps, impeller orientation is fixed and is not a factor in

pump performance; however, it must be carefully considered in multistage pumps,

which are available in two configurations: inline and opposed.

Inline configurations (see Figure 13–1) have all impellers facing in the same direc-

tion. As a result, the total differential pressure between the discharge and inlet is

axially applied to the rotating element toward the outboard bearing. Because of this

configuration, inline pumps are highly susceptible to changes in the operating

envelope.

Because of the tremendous axial pressures that are created by the inline design, these

pumps must have a positive means of limiting endplay, or axial movement, of the

rotating element. Normally, one of two methods is used to fix or limit axial move-

ment: (1) a large thrust bearing is installed at the outboard end of the pump to restrict

movement, or (2) discharge pressure is vented to a piston mounted on the outboard

end of the shaft.