Page 295 - Intro Predictive Maintenance

P. 295

286 An Introduction to Predictive Maintenance

14.1 COMMON GENERAL FAILURE MODES

Many of the common causes of failure in machinery components can be identified by

understanding their relationship to the true running speed of the shaft within the

machine-train.

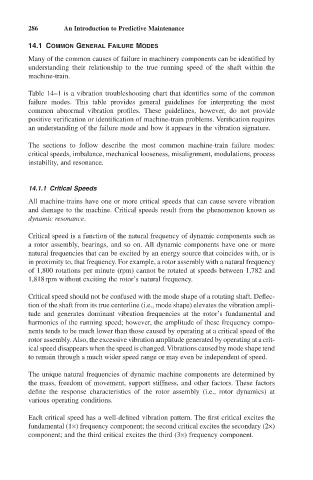

Table 14–1 is a vibration troubleshooting chart that identifies some of the common

failure modes. This table provides general guidelines for interpreting the most

common abnormal vibration profiles. These guidelines, however, do not provide

positive verification or identification of machine-train problems. Verification requires

an understanding of the failure mode and how it appears in the vibration signature.

The sections to follow describe the most common machine-train failure modes:

critical speeds, imbalance, mechanical looseness, misalignment, modulations, process

instability, and resonance.

14.1.1 Critical Speeds

All machine-trains have one or more critical speeds that can cause severe vibration

and damage to the machine. Critical speeds result from the phenomenon known as

dynamic resonance.

Critical speed is a function of the natural frequency of dynamic components such as

a rotor assembly, bearings, and so on. All dynamic components have one or more

natural frequencies that can be excited by an energy source that coincides with, or is

in proximity to, that frequency. For example, a rotor assembly with a natural frequency

of 1,800 rotations per minute (rpm) cannot be rotated at speeds between 1,782 and

1,818rpm without exciting the rotor’s natural frequency.

Critical speed should not be confused with the mode shape of a rotating shaft. Deflec-

tion of the shaft from its true centerline (i.e., mode shape) elevates the vibration ampli-

tude and generates dominant vibration frequencies at the rotor’s fundamental and

harmonics of the running speed; however, the amplitude of these frequency compo-

nents tends to be much lower than those caused by operating at a critical speed of the

rotor assembly. Also, the excessive vibration amplitude generated by operating at a crit-

ical speed disappears when the speed is changed. Vibrations caused by mode shape tend

to remain through a much wider speed range or may even be independent of speed.

The unique natural frequencies of dynamic machine components are determined by

the mass, freedom of movement, support stiffness, and other factors. These factors

define the response characteristics of the rotor assembly (i.e., rotor dynamics) at

various operating conditions.

Each critical speed has a well-defined vibration pattern. The first critical excites the

fundamental (1¥) frequency component; the second critical excites the secondary (2¥)

component; and the third critical excites the third (3¥) frequency component.