Page 316 - Intro Predictive Maintenance

P. 316

Failure-Mode Analysis 307

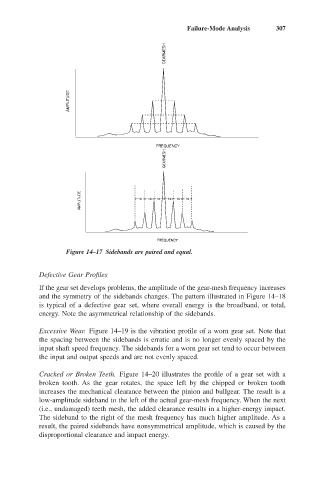

Figure 14–17 Sidebands are paired and equal.

Defective Gear Profiles

If the gear set develops problems, the amplitude of the gear-mesh frequency increases

and the symmetry of the sidebands changes. The pattern illustrated in Figure 14–18

is typical of a defective gear set, where overall energy is the broadband, or total,

energy. Note the asymmetrical relationship of the sidebands.

Excessive Wear. Figure 14–19 is the vibration profile of a worn gear set. Note that

the spacing between the sidebands is erratic and is no longer evenly spaced by the

input shaft speed frequency. The sidebands for a worn gear set tend to occur between

the input and output speeds and are not evenly spaced.

Cracked or Broken Teeth. Figure 14–20 illustrates the profile of a gear set with a

broken tooth. As the gear rotates, the space left by the chipped or broken tooth

increases the mechanical clearance between the pinion and bullgear. The result is a

low-amplitude sideband to the left of the actual gear-mesh frequency. When the next

(i.e., undamaged) teeth mesh, the added clearance results in a higher-energy impact.

The sideband to the right of the mesh frequency has much higher amplitude. As a

result, the paired sidebands have nonsymmetrical amplitude, which is caused by the

disproportional clearance and impact energy.