Page 313 - Intro Predictive Maintenance

P. 313

304 An Introduction to Predictive Maintenance

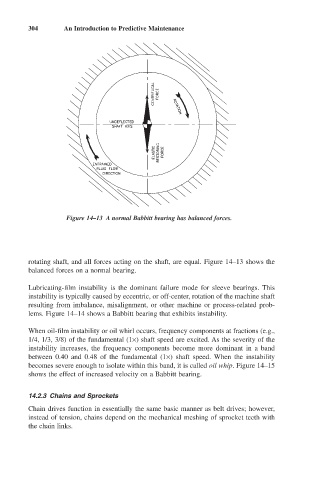

Figure 14–13 A normal Babbitt bearing has balanced forces.

rotating shaft, and all forces acting on the shaft, are equal. Figure 14–13 shows the

balanced forces on a normal bearing.

Lubricating-film instability is the dominant failure mode for sleeve bearings. This

instability is typically caused by eccentric, or off-center, rotation of the machine shaft

resulting from imbalance, misalignment, or other machine or process-related prob-

lems. Figure 14–14 shows a Babbitt bearing that exhibits instability.

When oil-film instability or oil whirl occurs, frequency components at fractions (e.g.,

1/4, 1/3, 3/8) of the fundamental (1¥) shaft speed are excited. As the severity of the

instability increases, the frequency components become more dominant in a band

between 0.40 and 0.48 of the fundamental (1¥) shaft speed. When the instability

becomes severe enough to isolate within this band, it is called oil whip. Figure 14–15

shows the effect of increased velocity on a Babbitt bearing.

14.2.3 Chains and Sprockets

Chain drives function in essentially the same basic manner as belt drives; however,

instead of tension, chains depend on the mechanical meshing of sprocket teeth with

the chain links.