Page 308 - Intro Predictive Maintenance

P. 308

Failure-Mode Analysis 299

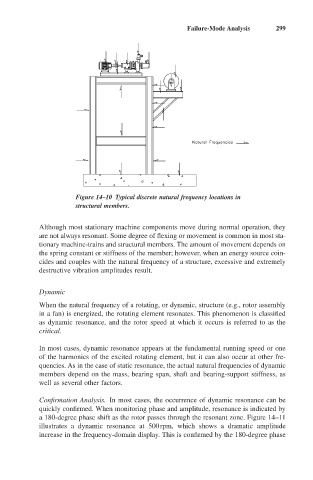

Figure 14–10 Typical discrete natural frequency locations in

structural members.

Although most stationary machine components move during normal operation, they

are not always resonant. Some degree of flexing or movement is common in most sta-

tionary machine-trains and structural members. The amount of movement depends on

the spring constant or stiffness of the member; however, when an energy source coin-

cides and couples with the natural frequency of a structure, excessive and extremely

destructive vibration amplitudes result.

Dynamic

When the natural frequency of a rotating, or dynamic, structure (e.g., rotor assembly

in a fan) is energized, the rotating element resonates. This phenomenon is classified

as dynamic resonance, and the rotor speed at which it occurs is referred to as the

critical.

In most cases, dynamic resonance appears at the fundamental running speed or one

of the harmonics of the excited rotating element, but it can also occur at other fre-

quencies. As in the case of static resonance, the actual natural frequencies of dynamic

members depend on the mass, bearing span, shaft and bearing-support stiffness, as

well as several other factors.

Confirmation Analysis. In most cases, the occurrence of dynamic resonance can be

quickly confirmed. When monitoring phase and amplitude, resonance is indicated by

a 180-degree phase shift as the rotor passes through the resonant zone. Figure 14–11

illustrates a dynamic resonance at 500rpm, which shows a dramatic amplitude

increase in the frequency-domain display. This is confirmed by the 180-degree phase