Page 329 - Intro Predictive Maintenance

P. 329

320 An Introduction to Predictive Maintenance

Figure 14–34 Eccentric sheaves.

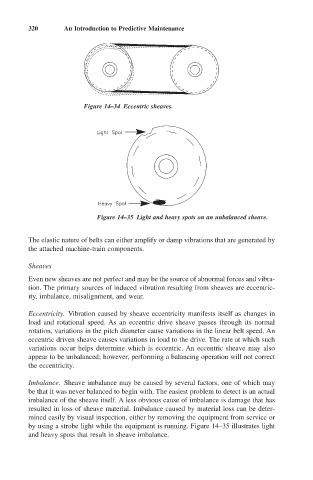

Figure 14–35 Light and heavy spots on an unbalanced sheave.

The elastic nature of belts can either amplify or damp vibrations that are generated by

the attached machine-train components.

Sheaves

Even new sheaves are not perfect and may be the source of abnormal forces and vibra-

tion. The primary sources of induced vibration resulting from sheaves are eccentric-

ity, imbalance, misalignment, and wear.

Eccentricity. Vibration caused by sheave eccentricity manifests itself as changes in

load and rotational speed. As an eccentric drive sheave passes through its normal

rotation, variations in the pitch diameter cause variations in the linear belt speed. An

eccentric driven sheave causes variations in load to the drive. The rate at which such

variations occur helps determine which is eccentric. An eccentric sheave may also

appear to be unbalanced; however, performing a balancing operation will not correct

the eccentricity.

Imbalance. Sheave imbalance may be caused by several factors, one of which may

be that it was never balanced to begin with. The easiest problem to detect is an actual

imbalance of the sheave itself. A less obvious cause of imbalance is damage that has

resulted in loss of sheave material. Imbalance caused by material loss can be deter-

mined easily by visual inspection, either by removing the equipment from service or

by using a strobe light while the equipment is running. Figure 14–35 illustrates light

and heavy spots that result in sheave imbalance.