Page 413 - Intro Predictive Maintenance

P. 413

404 An Introduction to Predictive Maintenance

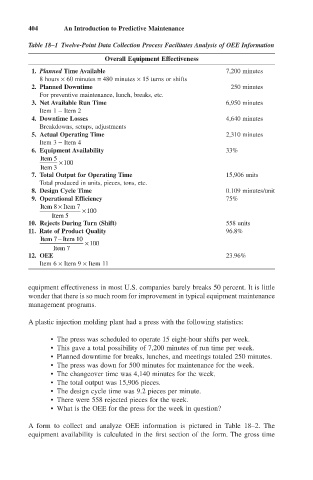

Table 18–1 Twelve-Point Data Collection Process Facilitates Analysis of OEE Information

Overall Equipment Effectiveness

1. Planned Time Available 7,200 minutes

8 hours ¥ 60 minutes = 480 minutes ¥ 15 turns or shifts

2. Planned Downtime 250 minutes

For preventive maintenance, lunch, breaks, etc.

3. Net Available Run Time 6,950 minutes

Item 1 - Item 2

4. Downtime Losses 4,640 minutes

Breakdowns, setups, adjustments

5. Actual Operating Time 2,310 minutes

Item 3 - Item 4

6. Equipment Availability 33%

Item 5

¥100

Item 3

7. Total Output for Operating Time 15,906 units

Total produced in units, pieces, tons, etc.

8. Design Cycle Time 0.109 minutes/unit

9. Operational Efficiency 75%

Item 8 ¥ Item 7

¥100

Item 5

10. Rejects During Turn (Shift) 558 units

11. Rate of Product Quality 96.8%

Item 7 Item 10

-

¥100

Item 7

12. OEE 23.96%

Item 6 ¥ Item 9 ¥ Item 11

equipment effectiveness in most U.S. companies barely breaks 50 percent. It is little

wonder that there is so much room for improvement in typical equipment maintenance

management programs.

A plastic injection molding plant had a press with the following statistics:

• The press was scheduled to operate 15 eight-hour shifts per week.

• This gave a total possibility of 7,200 minutes of run time per week.

• Planned downtime for breaks, lunches, and meetings totaled 250 minutes.

• The press was down for 500 minutes for maintenance for the week.

• The changeover time was 4,140 minutes for the week.

• The total output was 15,906 pieces.

• The design cycle time was 9.2 pieces per minute.

• There were 558 rejected pieces for the week.

• What is the OEE for the press for the week in question?

A form to collect and analyze OEE information is pictured in Table 18–2. The

equipment availability is calculated in the first section of the form. The gross time