Page 416 - Intro Predictive Maintenance

P. 416

World-Class Maintenance 407

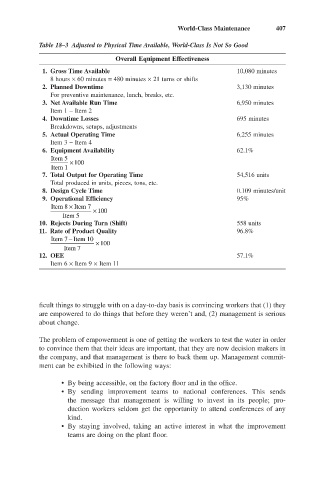

Table 18–3 Adjusted to Physical Time Available, World-Class Is Not So Good

Overall Equipment Effectiveness

1. Gross Time Available 10,080 minutes

8 hours ¥ 60 minutes = 480 minutes ¥ 21 turns or shifts

2. Planned Downtime 3,130 minutes

For preventive maintenance, lunch, breaks, etc.

3. Net Available Run Time 6,950 minutes

Item 1 - Item 2

4. Downtime Losses 695 minutes

Breakdowns, setups, adjustments

5. Actual Operating Time 6,255 minutes

Item 3 - Item 4

6. Equipment Availability 62.1%

Item 5

¥100

Item 1

7. Total Output for Operating Time 54,516 units

Total produced in units, pieces, tons, etc.

8. Design Cycle Time 0.109 minutes/unit

9. Operational Efficiency 95%

Item 8 ¥ Item 7

¥100

Item 5

10. Rejects During Turn (Shift) 558 units

11. Rate of Product Quality 96.8%

Item 7 Item 10

-

¥100

Item 7

12. OEE 57.1%

Item 6 ¥ Item 9 ¥ Item 11

ficult things to struggle with on a day-to-day basis is convincing workers that (1) they

are empowered to do things that before they weren’t and, (2) management is serious

about change.

The problem of empowerment is one of getting the workers to test the water in order

to convince them that their ideas are important, that they are now decision makers in

the company, and that management is there to back them up. Management commit-

ment can be exhibited in the following ways:

• By being accessible, on the factory floor and in the office.

• By sending improvement teams to national conferences. This sends

the message that management is willing to invest in its people; pro-

duction workers seldom get the opportunity to attend conferences of any

kind.

• By staying involved, taking an active interest in what the improvement

teams are doing on the plant floor.