Page 414 - Intro Predictive Maintenance

P. 414

World-Class Maintenance 405

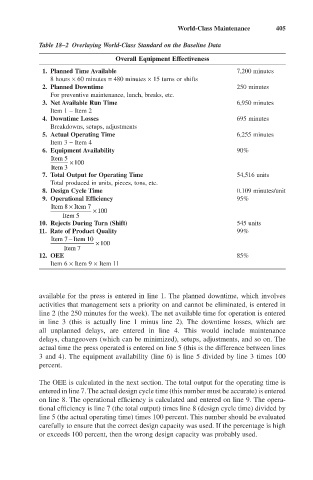

Table 18–2 Overlaying World-Class Standard on the Baseline Data

Overall Equipment Effectiveness

1. Planned Time Available 7,200 minutes

8 hours ¥ 60 minutes = 480 minutes ¥ 15 turns or shifts

2. Planned Downtime 250 minutes

For preventive maintenance, lunch, breaks, etc.

3. Net Available Run Time 6,950 minutes

Item 1 - Item 2

4. Downtime Losses 695 minutes

Breakdowns, setups, adjustments

5. Actual Operating Time 6,255 minutes

Item 3 - Item 4

6. Equipment Availability 90%

Item 5

¥100

Item 3

7. Total Output for Operating Time 54,516 units

Total produced in units, pieces, tons, etc.

8. Design Cycle Time 0.109 minutes/unit

9. Operational Efficiency 95%

Item 8 ¥ Item 7

¥100

Item 5

10. Rejects During Turn (Shift) 545 units

11. Rate of Product Quality 99%

Item 7 Item 10

-

¥100

Item 7

12. OEE 85%

Item 6 ¥ Item 9 ¥ Item 11

available for the press is entered in line 1. The planned downtime, which involves

activities that management sets a priority on and cannot be eliminated, is entered in

line 2 (the 250 minutes for the week). The net available time for operation is entered

in line 3 (this is actually line 1 minus line 2). The downtime losses, which are

all unplanned delays, are entered in line 4. This would include maintenance

delays, changeovers (which can be minimized), setups, adjustments, and so on. The

actual time the press operated is entered on line 5 (this is the difference between lines

3 and 4). The equipment availability (line 6) is line 5 divided by line 3 times 100

percent.

The OEE is calculated in the next section. The total output for the operating time is

entered in line 7. The actual design cycle time (this number must be accurate) is entered

on line 8. The operational efficiency is calculated and entered on line 9. The opera-

tional efficiency is line 7 (the total output) times line 8 (design cycle time) divided by

line 5 (the actual operating time) times 100 percent. This number should be evaluated

carefully to ensure that the correct design capacity was used. If the percentage is high

or exceeds 100 percent, then the wrong design capacity was probably used.