Page 67 - Intro Predictive Maintenance

P. 67

58 An Introduction to Predictive Maintenance

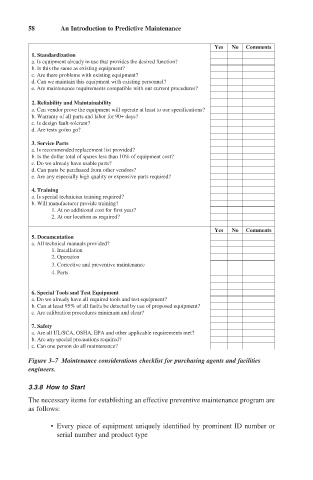

Yes No Comments

1. Standardization

a. Is equipment already in use that provides the desired function?

b. Is this the same as existing equipment?

c. Are there problems with existing equipment?

d. Can we maintain this equipment with existing personnel?

e. Are maintenance requirements compatible with our current procedures?

2. Reliability and Maintainability

a. Can vendor prove the equipment will operate at least to our specifications?

b. Warranty of all parts and labor for 90+ days?

c. Is design fault-tolerant?

d. Are tests go/no go?

3. Service Parts

a. Is recommended replacement list provided?

b. Is the dollar total of spares less than 10% of equipment cost?

c. Do we already have usable parts?

d. Can parts be purchased from other vendors?

e. Are any especially high quality or expensive parts required?

4. Training

a. Is special technician training required?

b. Will manufacturer provide training?

1. At no additional cost for first year?

2. At our location as required?

Yes No Comments

5. Documentation

a. All technical manuals provided?

1. Installation

2. Operation

3. Corrective and preventive maintenance

4. Parts

6. Special Tools and Test Equipment

a. Do we already have all required tools and test equipment?

b. Can at least 95% of all faults be detected by use of proposed equipment?

c. Are calibration procedures minimum and clear?

7. Safety

a. Are all UL/SCA, OSHA, EPA and other applicable requirements met?

b. Are any special precautions required?

c. Can one person do all maintenance?

Figure 3–7 Maintenance considerations checklist for purchasing agents and facilities

engineers.

3.3.8 How to Start

The necessary items for establishing an effective preventive maintenance program are

as follows:

• Every piece of equipment uniquely identified by prominent ID number or

serial number and product type