Page 63 - Intro Predictive Maintenance

P. 63

54 An Introduction to Predictive Maintenance

COMPARISON

(Benchmarking)

SHORT-TERM

TACTICS

CURRENT GOALS

VARIANCE MEASURE

PROCESS &

(Maintenance (Gap Analysis) (Where you want to be IMPLEMENTATION (How we are doing)

Evaluation) and When)

(How we get there)

LONG-TERM

STRATEGIES

IDEAL

(Duty-Task Analysis)

FEEDBACK

(Correction as required)

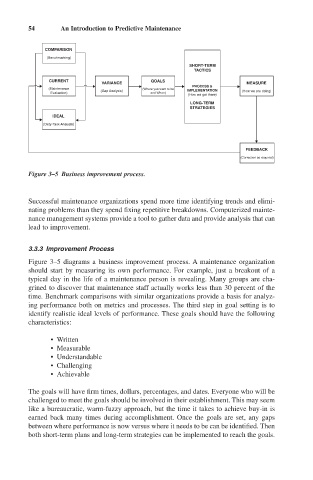

Figure 3–5 Business improvement process.

Successful maintenance organizations spend more time identifying trends and elimi-

nating problems than they spend fixing repetitive breakdowns. Computerized mainte-

nance management systems provide a tool to gather data and provide analysis that can

lead to improvement.

3.3.3 Improvement Process

Figure 3–5 diagrams a business improvement process. A maintenance organization

should start by measuring its own performance. For example, just a breakout of a

typical day in the life of a maintenance person is revealing. Many groups are cha-

grined to discover that maintenance staff actually works less than 30 percent of the

time. Benchmark comparisons with similar organizations provide a basis for analyz-

ing performance both on metrics and processes. The third step in goal setting is to

identify realistic ideal levels of performance. These goals should have the following

characteristics:

• Written

• Measurable

• Understandable

• Challenging

• Achievable

The goals will have firm times, dollars, percentages, and dates. Everyone who will be

challenged to meet the goals should be involved in their establishment. This may seem

like a bureaucratic, warm-fuzzy approach, but the time it takes to achieve buy-in is

earned back many times during accomplishment. Once the goals are set, any gaps

between where performance is now versus where it needs to be can be identified. Then

both short-term plans and long-term strategies can be implemented to reach the goals.