Page 60 - Intro Predictive Maintenance

P. 60

Role of Maintenance Organization 51

• Failures that can be prevented

• Maintenance to prevent failures

• Personnel

• Service Teams

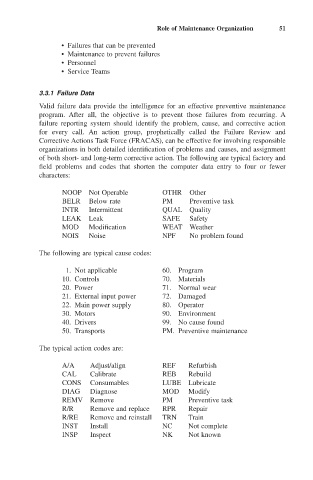

3.3.1 Failure Data

Valid failure data provide the intelligence for an effective preventive maintenance

program. After all, the objective is to prevent those failures from recurring. A

failure reporting system should identify the problem, cause, and corrective action

for every call. An action group, prophetically called the Failure Review and

Corrective Actions Task Force (FRACAS), can be effective for involving responsible

organizations in both detailed identification of problems and causes, and assignment

of both short- and long-term corrective action. The following are typical factory and

field problems and codes that shorten the computer data entry to four or fewer

characters:

NOOP Not Operable OTHR Other

BELR Below rate PM Preventive task

INTR Intermittent QUAL Quality

LEAK Leak SAFE Safety

MOD Modification WEAT Weather

NOIS Noise NPF No problem found

The following are typical cause codes:

1. Not applicable 60. Program

10. Controls 70. Materials

20. Power 71. Normal wear

21. External input power 72. Damaged

22. Main power supply 80. Operator

30. Motors 90. Environment

40. Drivers 99. No cause found

50. Transports PM. Preventive maintenance

The typical action codes are:

A/A Adjust/align REF Refurbish

CAL Calibrate REB Rebuild

CONS Consumables LUBE Lubricate

DIAG Diagnose MOD Modify

REMV Remove PM Preventive task

R/R Remove and replace RPR Repair

R/RE Remove and reinstall TRN Train

INST Install NC Not complete

INSP Inspect NK Not known