Page 151 - Introduction to Colloid and Surface Chemistry

P. 151

Th e solid-gas interface 141

Suppose that a primary Is electron is ejected, following which a 2s

electron falls into the vacant orbital and a 2p Auger electron is

ejected. Labelling these electrons K, LI and L2, respectively, this is a

KLL-type emission and the energy of the resulting Auger electron is

given by

£ A u g er='(K)-/(Ll)-/(L2) (5,15)

Since this is a function of ionisation energies only, it is not necessary

to use a monochromatic energy source,, which is an attractive

experimental feature of the technique. Indeed, Auger electrons can

be identified as such by their independence of the incident energy.

With many experimental features in common, it is possible to

construct a single instrument with facilities for XPS, AES, LEED and

certain other studies. The energy source for AES is usually an

electron beam, rather than X-rays. The disadvantage of an electron

beam is that it may cause structural damage. The advantage is that it

can be focussed (as in the electron microscope) and scanned over the

surface - scanning Auger electron spectroscopy (SAES). It is possible

14 2 8 2

to focus down t610" m and systematically scan an area of 10~ m .

+

A facility for sputter-ion etching by Ar ion bombardment can be

included. This enables the surface layers to be removed progressively

prior to studying the underlying surface features. AES is similar, in

principle, to SEM (see page 49) except that the latter employs an

incident electron beam of higher energy.

AES can be sensitive to as little as 1 per cent of a monolayer of

adsorbed material and is often used as a preliminary investigation of

the cleanliness of a surface prior to its study by LEED.

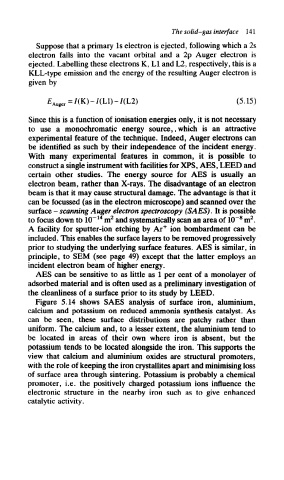

Figure 5.14 shows SAES analysis of surface iron, aluminium,

calcium and potassium on reduced ammonia synthesis catalyst. As

can be seen, these surface distributions are patchy rather than

uniform. The calcium and, to a lesser extent, the aluminium tend to

be located in areas of their own where iron is absent, but the

potassium tends to be located alongside the iron. This supports the

view that calcium and aluminium oxides are structural promoters,

with the role of keeping the iron crystallites apart and minimising loss

of surface area through sintering. Potassium is probably a chemical

promoter, i.e. the positively charged potassium ions influence the

electronic structure in the nearby iron such as to give enhanced

catalytic activity.