Page 378 - Introduction to Electronic Commerce and Social Commerce

P. 378

11.10 Solutions to Order Fulfillment Problems Along the Supply Chain 365

warehouse; receiving items at the receiving docks; and auto- structure connection between supply chain partners and ele-

mating the warehouse operations. For example, introducing ments is much shorter. Also, coordination and control is done

a make-to-order production process and providing timely at the center of the hub, making the management more effi-

and accurate demand information to suppliers can minimize cient, and the structure increases visibility. Long supply

inventories and out-of-stock incidents. In some instances, the chains are usually more susceptible to problems. Also, the

ultimate inventory improvement is to have no inventory at hub structure management is usually fully digital, making

all; for products that can be digitized (e.g., software), order order fulfillment faster, less expensive, and less problematic.

fulfillment can be instantaneous and can eliminate the need

for inventory.

Speeding Up Deliveries: From Same Day

to a Few Minutes

Changing the Structure and Process

of the Supply Chain As discussed earlier, a major success factor in EC is the

speed within which shoppers receive their orders. And

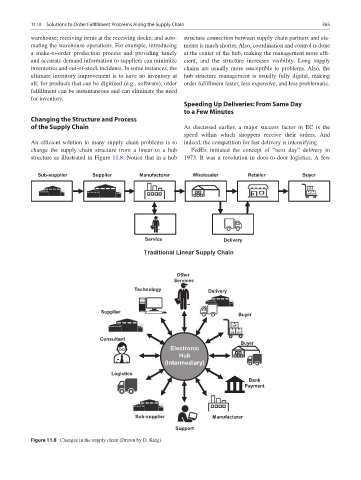

An efficient solution to many supply chain problems is to indeed, the competition for fast delivery is intensifying.

change the supply chain structure from a linear to a hub FedEx initiated the concept of “next day” delivery in

structure as illustrated in Figure 11.8. Notice that in a hub 1973. It was a revolution in door-to-door logistics. A few

Sub-supplier Supplier Manufacturer Wholesaler Retailer Buyer

Service Delivery

Traditional Linear Supply Chain

Other

Services

Technology Delivery

Supplier Buyer

Consultant Buyer

Electronic

Hub

(Intermediary)

Logistics

Bank

Payment

Sub-supplier Manufacturer

Support

Figure 11.8 Changes in the supply chain (Drawn by D. King)