Page 669 - Introduction to Information Optics

P. 669

! 1.4. Information Display Using Electro-Optic Spatial Light Modulators 653

coated with a thin electrically conductive but optically transparent metallic

film (such as indium-tin-oxide, ITO) called the alignment layer; then the layer

is rubbed with a fine cotton cloth in a unidirectional manner. Fine grooves

about several nanometers wide are formed by rubbing and thus cause the

liquid crystal molecules to lie parallel to the grooves. This rubbing method has

been widely used for fabricating large-panel LC devices. High-quality align-

ment can be made by vacuum deposition of a fine silicon monoxide (SiO) layer

to create microgroves onto the surface of the glass for aligning LC molecules.

If each alignment layer is polished with different directions, the molecular

orientation rotates helically about an axis normal to plates, such as the

situation shown in Fig. 11.29. The configuration shown in Fig. 11.29 is called

the twist alignment as the back glass plate is twisted at an angle with respect

to the front plate. Hence, if the alignment directions between the two plates are

90°, we have the perpendicular alignment. If the alignment directions are

parallel, the LC molecules are parallelly aligned, and we have parallel align-

ment [39].

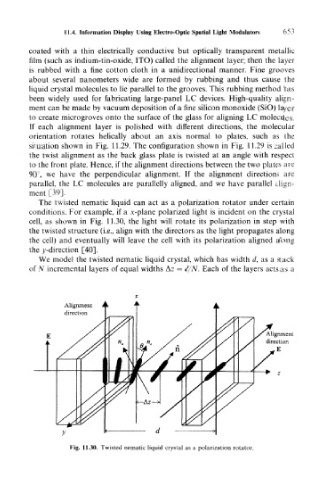

The twisted nematic liquid can act as a polarization rotator under certain

conditions. For example, if a x-plane polarized light is incident on the crystal

cell, as shown in Fig. 11.30, the light will rotate its polarization in step with

the twisted structure (i.e., align with the directors as the light propagates along

the cell) and eventually will leave the cell with its polarization aligned along

the v-direction [40].

We model the twisted nematic liquid crystal, which has width d, as a stack

of N incremental layers of equal widths Az = d/N. Each of the layers acts as a

Alignment

direction

/AliAlignment

direction

E

Fig. 11.30. Twisted nematic liquid crystal as a polarization rotator.