Page 339 - Introduction to Marine Engineering

P. 339

Instrumentation and control 313

This signal is fed to the controller where it is compared with the desired

value. The two-term controller will provide an output signal which is fed

to both control valves. Each valve is operated by a different range of

pressure with a 'dead band' between the ranges so that only one valve is

ever open at a time. The arrangement is shown in Figure 15.37. Thus if

the auxiliary range pressure is high the dump valve opens to release

steam. If the pressure is low the make-up valve opens to admit steam.

This split range control principle can be applied to a number of valves

if the controller output range is split appropriately.

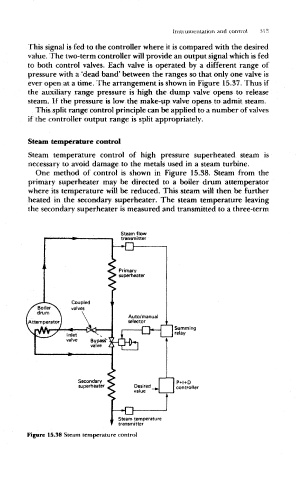

Steam temperature control of high pressure superheated steam is

necessary to avoid damage to the metals used in a steam turbine.

One method of control is shown in Figure 15.38. Steam from the

primary superheater may be directed to a boiler drum attemperator

where its temperature will be reduced. This steam will then be further

heated in the secondary superheater. The steam temperature leaving

the secondary superheater is measured and transmitted to a three-term

Steam temperature

transmitter

Figure 15.38 Steam temperature control