Page 337 - Introduction to Marine Engineering

P. 337

Instrumentation and control 311

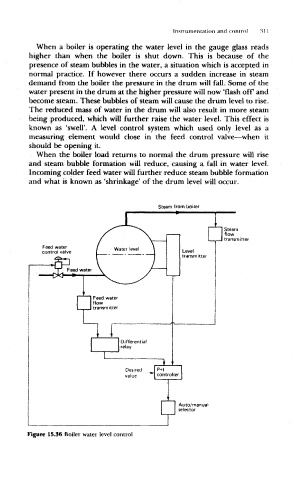

When a boiler is operating the water level in the gauge glass reads

higher than when the boiler is shut down. This is because of the

presence of steam bubbles in the water, a situation which is accepted in

normal practice. If however there occurs a sudden increase in steam

demand from the boiler the pressure in the drum will fail. Some of the

water present in the drum at the higher pressure will now 'flash off and

become steam. These bubbles of steam will cause the drum level to rise.

The reduced mass of water in the drum will also result in more steam

being produced, which will further raise the water level. This effect is

known as "swell', A level control system which used only level as a

measuring element would close in the feed control valve—when it

should be opening it.

When the boiler load returns to normal the drum pressure will rise

and steam bubble formation will reduce, causing a fall in water level.

Incoming colder feed water will further reduce steam bubble formation

and what is known as 'shrinkage' of the drum level will occur.

Steam from boiler

Auto/manual

selector

Figure 15.56 Boiler water level control