Page 338 - Introduction to Marine Engineering

P. 338

312 Instrumentation and control

The problems associated with swell and shrinkage are removed by the

use of a second measuring element, 'steam flow'. A third element, 'feed

water flow', is added to avoid problems that would occur if the feed

water pressure were to vary.

A three element control system is shown in Figure 15.$6. The

measured variables or elements are 'steam flow', 'drum level* and 'feed

water flow*. Since in a balanced situation steam flow must equal feed

flow, these two signals are compared in a differential relay. The relay

output is fed to a two-term controller and comparator into which the

measured drum level signal is also fed. Any deviation between the

desired and actual drum level and any deviation between feed and steam

flow will result in controller action to adjust the feed water control valve.

The drum level will then be returned to its correct position.

A sudden increase in steam demand would result in a deviation signal

from the differential relay and an output signal to open the feed water

control valve. The swell effect would therefore not influence the correct

operation of the control system. For a reduction in steam demand, an

output signal to close the feedwater control valve would result, thus

avoiding shrinkage effects. Any change in feed water pressure would

result in feed water control valve movement to correct the change before

the drum level was affected.

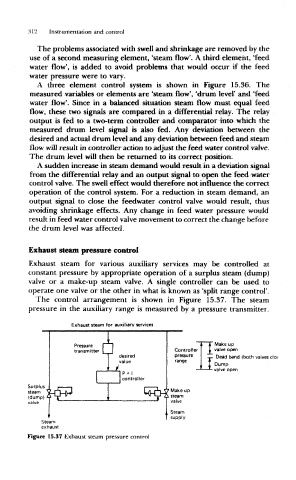

Exhaust steam pressure control

Exhaust steam for various auxiliary services may be controlled at

constant pressure by appropriate operation of a surplus steam (dump)

valve or a make-up steam valve, A single controller can be used to

operate one valve or the other in what is known as 'split range control*.

The control arrangement is shown in Figure 15.37. The steam

pressure in the auxiliary range is measured by a pressure transmitter.

Exhaust steam for auxiliary services

JL "

Pressure I n Make up

transmitter | | Controller valve open

J desired pressure Dead band {both valves cloj

value range

Dump

ii * valve open

P + 1

controller

Surplus • i * >

steam \Lrt-U LurHA ' Make up

(dump) A Y "^ i '* Y 21 steam

valve

Steam

supply

Steam

exhaust

Figure 15.37 Exhaust steam pressure control