Page 93 - Introduction to Marine Engineering

P. 93

80 Boilers

Furnace wall construction

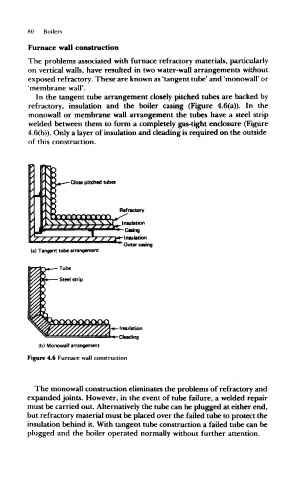

The problems associated with furnace refractory materials, particularly

on vertical walls, have resulted in two water-wall arrangements without

exposed refractory. These are known as 'tangent tube' and 'monowall' or

'membrane wall'.

In the tangent tube arrangement closely pitched tubes are backed by

refractory, insulation and the boiler casing (Figure 4.6(a)), In the

monowall or membrane wall arrangement the tubes have a steel strip

welded between them to form a completely gas-tight enclosure (Figure

4.6(b)). Only a layer of insulation and cleading is required on the outside

of this construction.

Close pitched tubes

Outer casing

(a) Tangent tube arrangement

Insulation

Cleading

(b) Monowall arrangement

Figure 4.6 Furnace wall construction

The monowall construction eliminates the problems of refractory and

expanded joints. However, in the event of tube failure, a welded repair

must be carried out. Alternatively the tube can be plugged at either end,

but refractory material must be placed over the failed tube to protect the

insulation behind it. With tangent tube construction a failed tube can be

plugged and the boiler operated normally without further attention.