Page 167 - Introduction to Petroleum Engineering

P. 167

154 DRILLING

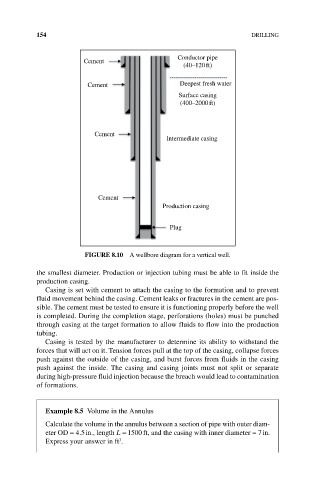

Conductor pipe

Cement

(40–120ft)

Cement Deepest fresh water

Surface casing

(400–2000ft)

Cement

Intermediate casing

Cement

Production casing

Plug

FIGuRe 8.10 A wellbore diagram for a vertical well.

the smallest diameter. Production or injection tubing must be able to fit inside the

production casing.

Casing is set with cement to attach the casing to the formation and to prevent

fluid movement behind the casing. Cement leaks or fractures in the cement are pos-

sible. The cement must be tested to ensure it is functioning properly before the well

is completed. During the completion stage, perforations (holes) must be punched

through casing at the target formation to allow fluids to flow into the production

tubing.

Casing is tested by the manufacturer to determine its ability to withstand the

forces that will act on it. Tension forces pull at the top of the casing, collapse forces

push against the outside of the casing, and burst forces from fluids in the casing

push against the inside. The casing and casing joints must not split or separate

during high‐pressure fluid injection because the breach would lead to contamination

of formations.

example 8.5 Volume in the Annulus

Calculate the volume in the annulus between a section of pipe with outer diam-

eter OD = 45 in., length L = 1500 ft, and the casing with inner diameter = 7 in.

.

3

Express your answer in ft .