Page 197 - Introduction to chemical reaction engineering and kinetics

P. 197

8.1 Catalysis and Catalysts 179

reaction rates (this is developed in Section 8.5). Approximately 80% of commer-

cial catalytic reactions involve heterogeneous catalysis. This is due to the gener-

ally greater flexibility compared with homogeneous catalysis, and to the added

cost of separation of the catalyst from a homogeneous system.

8.1.3 General Aspects of Catalysis

8.1.3.1 Catalytic Sites

Central to catalysis is the notion of the catalytic “site.” It is defined as the catalytic

center involved in the reaction steps, and, in Figure 8.1, is the molybdenum atom

where the reactions take place. Since all catalytic centers are the same for molec-

ular catalysts, the elementary steps are bimolecular or unimolecular steps with the

same rate laws which characterize the homogeneous reactions in Chapter 7. How-

ever, if the reaction takes place in solution, the individual rate constants may de-

pend on the nonreactive ligands and the solution composition in addition to tempera-

ture.

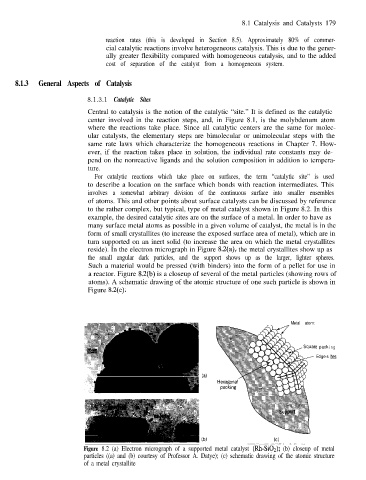

For catalytic reactions which take place on surfaces, the term “catalytic site” is used

to describe a location on the surface which bonds with reaction intermediates. This

involves a somewhat arbitrary division of the continuous surface into smaller ensembles

of atoms. This and other points about surface catalysts can be discussed by reference

to the rather complex, but typical, type of metal catalyst shown in Figure 8.2. In this

example, the desired catalytic sites are on the surface of a metal. In order to have as

many surface metal atoms as possible in a given volume of catalyst, the metal is in the

form of small crystallites (to increase the exposed surface area of metal), which are in

turn supported on an inert solid (to increase the area on which the metal crystallites

reside). In the electron micrograph in Figure 8.2(a), the metal crystallites show up as

the small angular dark particles, and the support shows up as the larger, lighter spheres.

Such a material would be pressed (with binders) into the form of a pellet for use in

a reactor. Figure 8.2(b) is a closeup of several of the metal particles (showing rows of

atoms). A schematic drawing of the atomic structure of one such particle is shown in

Figure 8.2(c).

Metal atom:

-e pack i n g

Edge s ,ites

(a)

(b)

Figure 8.2 (a) Electron micrograph of a supported metal catalyst (Rh-SiO,); (b) closeup of metal

particles ((a) and (b) courtesy of Professor A. Datye); (c) schematic drawing of the atomic structure

of a metal crystallite