Page 115 - Know and Understand Centrifugal Pumps

P. 115

Know and Understand Centrifugal Pumps

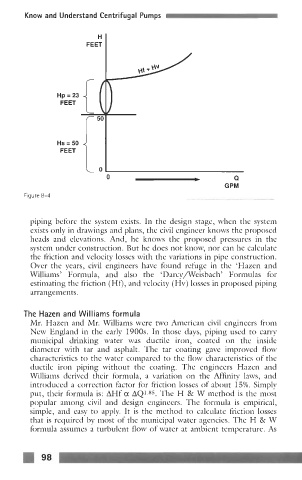

FEET I

H

Hp = 23

FEET

HS = 50

FEET

piping before the system exists. In the design stage, when the system

exists only in drawings and plans, the civil engineer knows the proposed

heads and elevations. And, he knows the proposed pressures in the

system under construction. But he does not know, nor can he calculate

the friction and velocity losses with the variations in pipe construction.

Over the years, civil engineers have found refuge in the ‘Hazen and

Williams’ Formula, and also the ‘Darcy/Weisbach’ Formulas for

estimating the friction (Hf), and velocity (Hv) losses in proposed piping

arrangements.

The Hazen and Williams formula

Mr. Hazen and Mr. Williams were two American civil engineers from

New England in the early 1900s. In those days, piping used to carry

municipal drinking water was ductile iron, coated on the inside

diameter with tar and asphalt. The tar coating gave improved flow

characteristics to the water compared to the flow characteristics of the

ductile iron piping without the coating. The engineers Hazen and

Williams derived their formula, a variation on the Affinity laws, and

introduced a correction factor for friction losses of about 15%. Simply

put, their formula is: AHf a AQl.85. The H & W method is the most

popular among civil and design engineers. The formula is empirical,

simple, and easy to apply. It is the method to calculate friction losses

that is required by most of the municipal water agencies. The H & W

formula assumes a turbulent flow of water at ambient temperature. As

F1 98