Page 202 - Know and Understand Centrifugal Pumps

P. 202

Mechanical Seals

As the faces wear, the spring extends maintaining the rotary face in

contact with the stationary face. The shaft O-ring should be free to

move axially on the shaft within the operational tolerances of the

bearings. This is called axial play.

The liquid’s pressure in the seal chamber holds the faces together and

also provides a thin film of lubrication between the faces. This lubricant

is the pumped product. The faces, selected for their low frictional

characteristics, are the only parts of the seal in relative motion. Other

parts would be in relative motion if the equipment is misaligned or with

loose tolerance in the bearings.

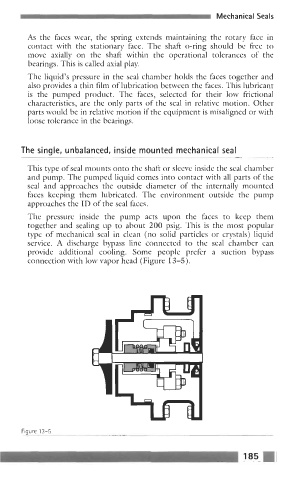

The single, unbalanced, inside mounted mechanical seal

This type of seal mounts onto the shaft or sleeve inside the seal chamber

and pump. The pumped liquid comes into contact with all parts of the

seal and approaches the outside diameter of the internally mounted

faces keeping them lubricated. The environment outside the pump

approaches the ID of the seal faces.

The pressure inside the pump acts upon the faces to keep them

together and sealing up to about 200 psig. This is the most popular

type of mechanical seal in clean (no solid particles or crystals) liquid

service. A discharge bypass line connected to the seal chamber can

provide additional cooling. Some people prefer a suction bypass

connection with low vapor head (Figure 13-5).

Fiaure 13-5

185