Page 203 - Know and Understand Centrifugal Pumps

P. 203

Know and Understand Centrifugal Pumps

The single, outside-mounted, unbalanced seal

This type of seal has the rotary component and face mounted outside

the seal chamber. The springs and drive elements are outside the

pumped liquid. This reduces the problems associated with corrosion

and the accumulation of pumped product clogging the springs. This

seal is popular in the food processing industry. The pumped liquid

arrives to the inside diameter of the faces and seals toward the outside

diameter. The environment outside the pump approaches the OD of

the face union. Pressures are limited to about 35 psig. Sometimes this

seal can be mounted either inside or outside the pump. This seal is easy

to install, adjust, and maintain. It permits easy access and cleaning of

the pump internal parts, often required in the food processing industry.

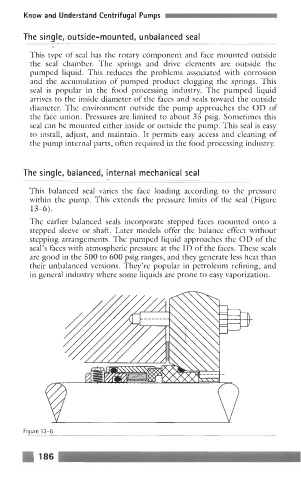

The single, balanced, internal mechanical seal

This balanced seal varies the face loading according to the pressure

within the pump. This extends the pressure limits of the seal (Figure

13-6).

The earlier balanced seals incorporate stepped faces mounted onto a

stepped sleeve or shaft. Later models offer the balance effect without

stepping arrangements. The pumped liquid approaches the OD of the

seal’s faces with atmospheric pressure at the ID of the faces. These seals

are good in the 500 to 600 psig ranges, and they generate less heat than

their unbalanced versions. They’re popular in petroleum refining, and

in general industry where some liquids are prone to easy vaporization.

Figure 13-6

186