Page 49 - Know and Understand Centrifugal Pumps

P. 49

Know and Understand Centrifugal Pumps

Internal re-circulation

This is a low flow condition where the discharge flow of the pump is

restricted and the product cannot leave the pump. The liquid is forced

to recirculate from high-pressure zones in the pump into low-pressure

zones across the impeller.

This type of cavitation originates from two sources. First, the liquid is

circulating inside the volute of the pump at the speed of the motor and

it rapidly overheats. Second, the liquid is forced to pass through tight

tolerances at very high speed. (These tight tolerances are across the

wear bands on enclosed impellers, and between the impeller’s leading

edges and the volute casing on opened impellers.) The heat and the

high velocity cause the liquid to vaporize.

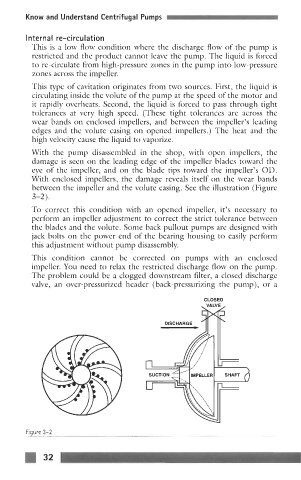

With the pump disassembled in the shop, with open impellers, the

damage is seen on the leading edge of the impeller blades toward the

eye of the impeller, and on the blade tips toward the impeller’s OD.

With enclosed impellers, the damage reveals itself on the wear bands

between the impeller and the volute casing. See the illustration (Figure

3-2).

To correct this condition with an opened impeller, it’s necessary to

perform an impeller adjustment to correct the strict tolerance between

the blades and the volute. Some back pullout pumps are designed with

jack bolts on the power end of the bearing housing to easily perform

this adjustment without pump disassembly.

This condition cannot be corrected on pumps with an enclosed

impeller. You need to relax the restricted discharge flow on the pump.

The problem could be a clogged downstream filter, a closed discharge

valve, an over-pressurized header (back-pressurizing the pump), or a

CLOSED

-

DISCHARGE

Figure 3-2

-~

~