Page 50 - Know and Understand Centrifugal Pumps

P. 50

Cavitation

check valve installed backwards, or operating the pump at or close to

shut-off head. Maybe a variable speed motor could help under certain

circumstances.

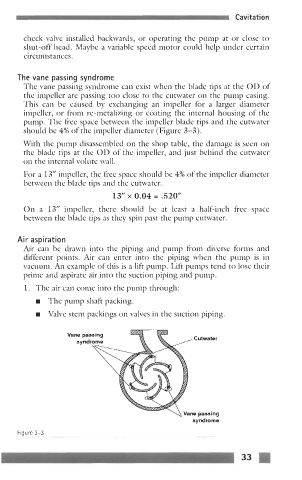

The vane passing syndrome

The vane passing syndrome can exist when the blade tips at the OD of

the impeller are passing too close to the cutwater on the pump casing.

This can be caused by exchanging an impeller for a larger diameter

impeller, or from re-metalizing or coating the internal housing of the

pump. The free space between the impeller blade tips and the cutwater

should be 4% of the impeller diameter (Figure 3-3).

With the pump disassembled on the shop table, the damage is seen on

the blade tips at the OD of the impeller, and just behind the cutwater

on the internal volute wall.

For a 13“ impeller, the free space should be 4% of the impeller diameter

between the blade tips and the cutwater.

13” x 0.04 = .520”

On a 13” impeller, there should be at least a half-inch free space

between the blade tips as they spin past the pump cutwater.

Air aspiration

Air can be drawn into the piping and pump from diverse forms and

different points. Air can enter into the piping when the pump is in

vacuum. An example of this is a lift pump. Lift pumps tend to lose their

prime and aspirate air into the suction piping and pump.

1. The air can come into the pump through:

w The pump shaft packing.

w Valve stem packings on valves in the suction piping.

syndrome

Figure 3-3

~. .