Page 55 - Know and Understand Centrifugal Pumps

P. 55

Know and Understand Centrifugal Pumps

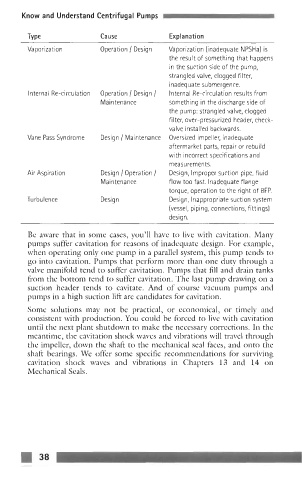

Type Cause Explanation

Vaporization Operation / Design Vaporization (inadequate NPSHa) is

the result of something that happens

in the suction side of the pump,

strangled valve, clogged filter,

inadequate submergence.

Internal Re-circulation Operation / Design / Internal Re-circulation results from

Ma in tena nce something in the discharge side of

the pump: strangled valve, clogged

filter, over-pressurized header, check-

valve installed backwards.

Vane Pass Syndrome Design / Maintenance Oversized impeller, inadequate

aftermarket parts, repair or rebuild

with incorrect specifications and

measurements.

Air Aspiration Design / Operation / Design, Improper suction pipe, fluid

Ma in tena nce flow too fast. Inadequate flange

torque, operation to the right of BEP.

Turbulence Design Design, Inappropriate suction system

(vessel, piping, connections, fittings)

design.

Be aware that in some cases, you’ll have to live with cavitation. Many

pumps suffer cavitation for reasons of inadequate design. For example,

when operating only one pump in a parallel system, this pump tends to

go into cavitation. Pumps that perform more than one duty through a

valve manifold tend to suffer cavitation. Pumps that fill and drain tanks

from the bottom tend to suffer cavitation. The last pump drawing on a

suction header tends to cavitate. And of course vacuum pumps and

pumps in a high suction lift are candidates for cavitation.

Some solutions may not be practical, or economical, or timely and

consistent with production. You could be forced to live with cavitation

until the next plant shutdown to make the necessary corrections. In the

meantime, the cavitation shock waves and vibrations will travel through

the impeller, down the shaft to the mechanical seal faces, and onto the

shaft bearings. We offer some specific recommendations for surviving

cavitation shock waves and vibrations in Chapters 13 and 14 on

Mechanical Seals.

n 38