Page 39 - Materials Chemistry, Second Edition

P. 39

20 LIFE CYCLE ASSESSMENT HANDBOOK

LCA is primarily a quantitative model. In the LCI, all unit processes

included have to be quantified. This means that we have to specify the sizes of

the inflows and outflows, per unit process. As an example, let us take the unit

process of aluminum production.

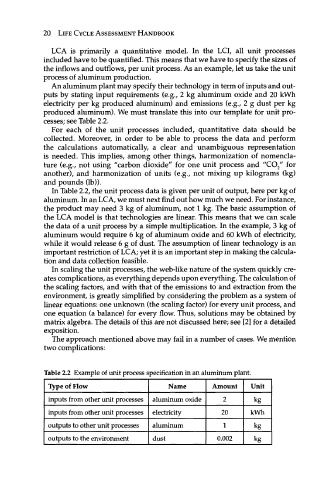

An aluminum plant may specify their technology in term of inputs and out-

puts by stating input requirements (e.g., 2 kg aluminum oxide and 20 kWh

electricity per kg produced aluminum) and emissions (e.g., 2 g dust per kg

produced aluminum). We must translate this into our template for unit pro-

cesses; see Table 2.2.

For each of the unit processes included, quantitative data should be

collected. Moreover, in order to be able to process the data and perform

the calculations automatically, a clear and unambiguous representation

is needed. This implies, among other things, harmonization of nomencla-

ture (e.g., not using "carbon dioxide" for one unit process and "C0 2 " for

another), and harmonization of units (e.g., not mixing up kilograms (kg)

and pounds (lb)).

In Table 2.2, the unit process data is given per unit of output, here per kg of

aluminum. In an LCA, we must next find out how much we need. For instance,

the product may need 3 kg of aluminum, not 1 kg. The basic assumption of

the LCA model is that technologies are linear. This means that we can scale

the data of a unit process by a simple multiplication. In the example, 3 kg of

aluminum would require 6 kg of aluminum oxide and 60 kWh of electricity,

while it would release 6 g of dust. The assumption of linear technology is an

important restriction of LCA; yet it is an important step in making the calcula-

tion and data collection feasible.

In scaling the unit processes, the web-like nature of the system quickly cre-

ates complications, as everything depends upon everything. The calculation of

the scaling factors, and with that of the emissions to and extraction from the

environment, is greatly simplified by considering the problem as a system of

linear equations: one unknown (the scaling factor) for every unit process, and

one equation (a balance) for every flow. Thus, solutions may be obtained by

matrix algebra. The details of this are not discussed here; see [2] for a detailed

exposition.

The approach mentioned above may fail in a number of cases. We mention

two complications:

Table 2.2 Example of unit process specification in an aluminum plant.

Type of Flow Name Amount Unit

inputs from other unit processes aluminum oxide 2 kg

inputs from other unit processes electricity 20 kWh

outputs to other unit processes aluminum 1 kg

outputs to the environment dust 0.002 kg