Page 67 - Materials Chemistry, Second Edition

P. 67

LIFE CYCLE INVENTORY MODELING IN PRACTICE 49

Methanol recycle

w

Natural g Methanol DMT Melt phase and

production manufacture manufacture solid state PET h

polymerization

from DMT

TPA

Acetic acid

manufacture manufacture

Natural gas (1) Melt phase and

PTA solid state PET h

manufacture t polymerization

Carbon from PTA

monoxide

manufacture

Ethylene I Ethylene |

Crude oil Ethylen« oxide I H glycol 1

production manufacture I manufacture I manufacture I

ture

Distillation/

desalting

Hydrotreating

Paraxylene

Mixed H

xylenes extraction

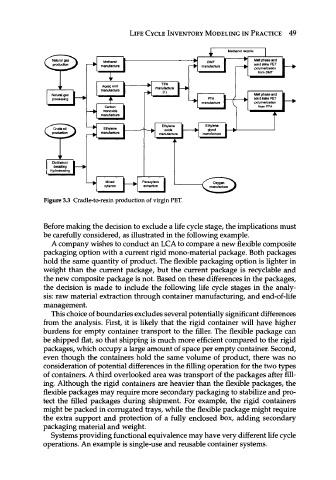

Figure 3.3 Cradle-to-resin production of virgin PET.

Before making the decision to exclude a life cycle stage, the implications must

be carefully considered, as illustrated in the following example.

A company wishes to conduct an LCA to compare a new flexible composite

packaging option with a current rigid mono-material package. Both packages

hold the same quantity of product. The flexible packaging option is lighter in

weight than the current package, but the current package is recyclable and

the new composite package is not. Based on these differences in the packages,

the decision is made to include the following life cycle stages in the analy-

sis: raw material extraction through container manufacturing, and end-of-life

management.

This choice of boundaries excludes several potentially significant differences

from the analysis. First, it is likely that the rigid container will have higher

burdens for empty container transport to the filler. The flexible package can

be shipped flat, so that shipping is much more efficient compared to the rigid

packages, which occupy a large amount of space per empty container. Second,

even though the containers hold the same volume of product, there was no

consideration of potential differences in the filling operation for the two types

of containers. A third overlooked area was transport of the packages after fill-

ing. Although the rigid containers are heavier than the flexible packages, the

flexible packages may require more secondary packaging to stabilize and pro-

tect the filled packages during shipment. For example, the rigid containers

might be packed in corrugated trays, while the flexible package might require

the extra support and protection of a fully enclosed box, adding secondary

packaging material and weight.

Systems providing functional equivalence may have very different life cycle

operations. An example is single-use and reusable container systems.