Page 127 - Materials Chemistry, Second Edition

P. 127

Life Cycle Assessment of Biodiesel from Palm Oil 113

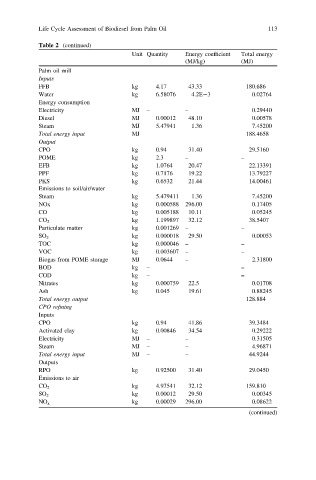

Table 2 (continued)

Unit Quantity Energy coefficient Total energy

(MJ/kg) (MJ)

Palm oil mill

Inputs

FFB kg 4.17 43.33 180.686

Water kg 6.58076 4.2E-3 0.02764

Energy consumption

Electricity MJ – – 0.29440

Diesel MJ 0.00012 48.10 0.00578

Steam MJ 5.47941 1.36 7.45200

Total energy input MJ 188.4658

Output

CPO kg 0.94 31.40 29.5160

POME kg 2.3 – –

EFB kg 1.0764 20.47 22.13391

PPF kg 0.7176 19.22 13.79227

PKS kg 0.6532 21.44 14.00461

Emissions to soil/air/water

Steam kg 5.479411 1.36 7.45200

NOx kg 0.000588 296.00 0.17405

CO kg 0.005188 10.11 0.05245

kg 1.199897 32.12 38.5407

CO 2

Particulate matter kg 0.001269 – –

SO 2 kg 0.000018 29.50 0.00053

TOC kg 0.000046 – –

VOC kg 0.003607 – –

Biogas from POME storage MJ 0.0644 – 2.31800

BOD kg – –

COD kg – –

Nitrates kg 0.000759 22.5 0.01708

Ash kg 0.045 19.61 0.88245

Total energy output 128.884

CPO refining

Inputs

CPO kg 0.94 41.86 39.3484

Activated clay kg 0.00846 34.54 0.29222

Electricity MJ – – 0.31505

Steam MJ – – 4.96871

Total energy input MJ – – 44.9244

Outputs

RPO kg 0.92500 31.40 29.0450

Emissions to air

kg 4.97541 32.12 159.810

CO 2

kg 0.00012 29.50 0.00345

SO 2

kg 0.00029 296.00 0.08622

NO x

(continued)