Page 193 - Materials Chemistry, Second Edition

P. 193

Sustainability of (H 2 ? CH 4 ) by Anaerobic Digestion 181

necessary to run the bioreactor. A detailed analysis of the net energy production of

two-steps AD can be found in (Ruggeri et al. 2010) and only a brief introduction is

given here. The net energy production E net may be calculated as:

ð3Þ

E net ¼ E H2 þ CH 4 E h þ E hp þ E l þ E m þ E p

where

is the energy produced (MJ/L)

E H2+CH4

is the heating energy necessary to reach the working temperature (MJ/

E h

L)

is the heating energy necessary to reach the pretreatment temperature

E hp

(MJ/L) if a thermal pretreatment is present

is the thermal energy loss, which depends on the outdoor ambient

E l

temperature and the duration of the fermentation (MJ/L)

E m is the electrical energy consumed for mixing (MJ/L) if a mixing system

is present

is the electrical energy consumed for pumping (MJ/L)

E p

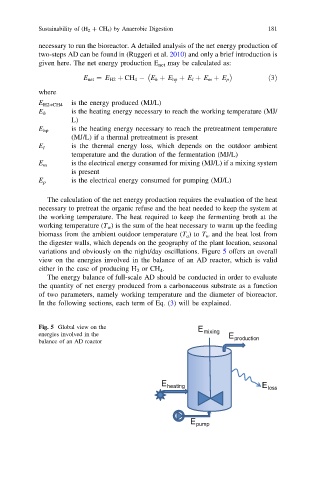

The calculation of the net energy production requires the evaluation of the heat

necessary to pretreat the organic refuse and the heat needed to keep the system at

the working temperature. The heat required to keep the fermenting broth at the

working temperature (T w ) is the sum of the heat necessary to warm up the feeding

biomass from the ambient outdoor temperature (T a )to T w and the heat lost from

the digester walls, which depends on the geography of the plant location, seasonal

variations and obviously on the night/day oscillations. Figure 5 offers an overall

view on the energies involved in the balance of an AD reactor, which is valid

either in the case of producing H 2 or CH 4 .

The energy balance of full-scale AD should be conducted in order to evaluate

the quantity of net energy produced from a carbonaceous substrate as a function

of two parameters, namely working temperature and the diameter of bioreactor.

In the following sections, each term of Eq. (3) will be explained.

Fig. 5 Global view on the E

energies involved in the mixing E

balance of an AD reactor production

E heating E loss

E pump