Page 34 - Lignocellulosic Biomass to Liquid Biofuels

P. 34

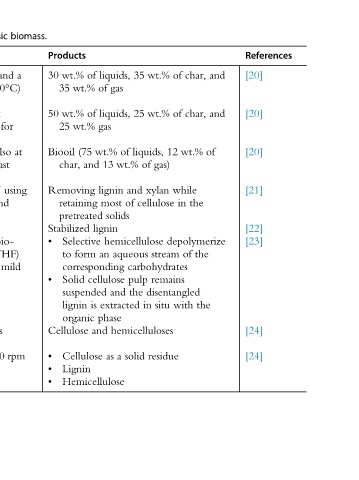

References [20] [20] [20] [21] [22] [23] [24] [24]

and and of

char, char, wt.% the depolymerize the of the

of of 12 while in remains disentangled with

wt.% wt.% gas) xylan cellulose stream carbohydrates situ residue

35 25 liquids, of wt.% and of hemicellulose aqueous pulp the in hemicelluloses solid

liquids, gas liquids, gas of wt.% 13 lignin most solids lignin an cellulose and extracted phase a as

of of wt.% of wt.% (75 and pretreated Selective form corresponding suspended is and Cellulose Hemicellulose

Products wt.% 30 35 wt.% 50 25 Biooil char, Removing retaining Stabilized • to Solid • lignin organic Cellulose • Lignin • •

biomass. a and for at using bio- mild rpm

lignocellulosic min) (290°C 400°C) at s 10 30 500°C) also s) (w1 fast for 500°C W 800 at and chloride and water (2-MeTHF) at catalyst conditions 100 and

of ( . 10 time of (around time of irradiation choline as acid 140°C) 50°C

process residence temperature time temperature pyrolysis residence temperature of (ChCl:LA) comprising 2-methyltetrahydrofuran oxalic to nonisothermal v/v), (80%,

fractionation conditions vapor operating pyrolysis slow residence hot-vapor moderate intermediate hot-vapor moderate microwave composed acid h 6 7 system and solvents (up temperatures under acid h 24

developed Process long A low for A short A a pyrolysis with s 45 DES a lactic Requires biphasic A based as 180°C At Phosphoric for solvents.

Recently DES and eutectic

1.3 Fractionation Microwave- assisted Aldehydes OrganoCat Hydrothermal delignification Organosolv Deep

Table Pyrolysis DES,