Page 79 - Lignocellulosic Biomass to Liquid Biofuels

P. 79

is to

sugars pressure usually and explosion and The single- the in high

of High is biomass satisfying so CO 2 biomass recovery formed well increased. the exit also alkaline

decomposition inhibitors. explosion Steam grass not but biomass. dry to chemical sulfur-containing the if not is is complexity in encountered pretreatment and acid Relatively costs

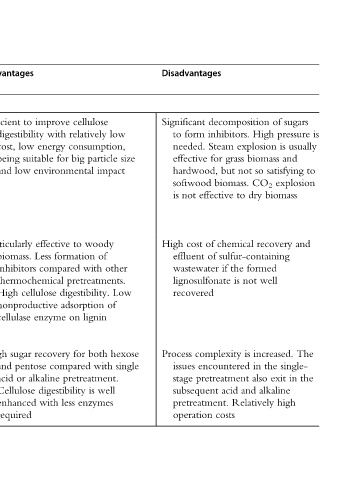

Disadvantages Significant form to needed. for effective hardwood, softwood effective not is of cost High of effluent wastewater lignosulfonate recovered Process issues stage subsequent pretreatment. operation

size hexose single

low impact other Low of well

cellulose relatively consumption, particle big woody to of formation with pretreatments. digestibility. adsorption lignin on both for with pretreatment. is enzymes

improve with energy for suitable environmental effective Less compared cellulose enzyme recovery compared alkaline digestibility less with

Advantages to Efficient digestibility low cost, being low and Particularly biomass. inhibitors thermochemical High nonproductive cellulase sugar High pentose and or acid Cellulose enhanced required

high- duration (for of make

to with is explosive cell and chips a with part with to wall accessibility respectively

mechanisms digestibility heated or steam short a for pressure causing deconstruct significant structure lignin wood reduction considerable removed Lignin modified Cell deconstructed cellulose alkaline and remove lignin

and are saturated CO 2 the then to with hemicelluloses of soften size A is delignification. greatly hydrophilic. greatly in acid of to and process

action cellulose substrates and reduced decompression structure of explosion) to sulfite by milling. hemicelluloses is is increase hemicelluloses multistage

of pressure supercritical time swiftly removal modification stem followed partial structure more structure with Combination pretreatment a

Mode improve Biomass of wall Using disk it in

(Continued) pretreatment CO 2 etc.) acid

2.2 Pretreatment Physicochemical pretreatment (steam explosion, explosion, Subsequent alkaline pretreatment

Table methods Combined SPROL and