Page 98 - Lindens Handbook of Batteries

P. 98

FACTORS AFFECTING BATTERY PERFORMANCE 3.17

3.2.10 Charging Voltage

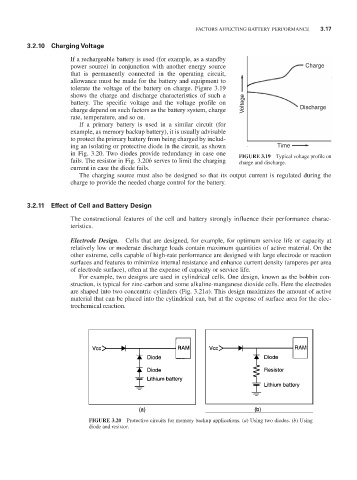

If a rechargeable battery is used (for example, as a standby

power source) in conjunction with another energy source Charge

that is permanently connected in the operating circuit,

allowance must be made for the battery and equipment to

tolerate the voltage of the battery on charge. Figure 3.19

shows the charge and discharge characteristics of such a

battery. The specific voltage and the voltage profile on Voltage

charge depend on such factors as the battery system, charge Discharge

rate, temperature, and so on.

If a primary battery is used in a similar circuit (for

example, as memory backup battery), it is usually advisable

to protect the primary battery from being charged by includ-

ing an isolating or protective diode in the circuit, as shown Time

in Fig. 3.20. Two diodes provide redundancy in case one FIGURE 3.19 Typical voltage profile on

fails. The resistor in Fig. 3.20b serves to limit the charging charge and discharge.

current in case the diode fails.

The charging source must also be designed so that its output current is regulated during the

charge to provide the needed charge control for the battery.

3.2.11 Effect of Cell and Battery Design

The constructional features of the cell and battery strongly influence their performance charac-

teristics.

Electrode Design. Cells that are designed, for example, for optimum service life or capacity at

relatively low or moderate discharge loads contain maximum quantities of active material. On the

other extreme, cells capable of high-rate performance are designed with large electrode or reaction

surfaces and features to minimize internal resistance and enhance current density (amperes per area

of electrode surface), often at the expense of capacity or service life.

For example, two designs are used in cylindrical cells. One design, known as the bobbin con-

struction, is typical for zinc-carbon and some alkaline-manganese dioxide cells. Here the electrodes

are shaped into two concentric cylinders (Fig. 3.21a). This design maximizes the amount of active

material that can be placed into the cylindrical can, but at the expense of surface area for the elec-

trochemical reaction.

FIGURE 3.20 Protective circuits for memory backup applications. (a) Using two diodes. (b) Using

diode and resistor.